About Me

I am currently a student at Texas A&M University, majoring in Mechanical Engineering with a Minor in Engineering Entrepreneurship.

I will be graduating in May 2025 with a Bachelor of Science in Mechanical Engineering.

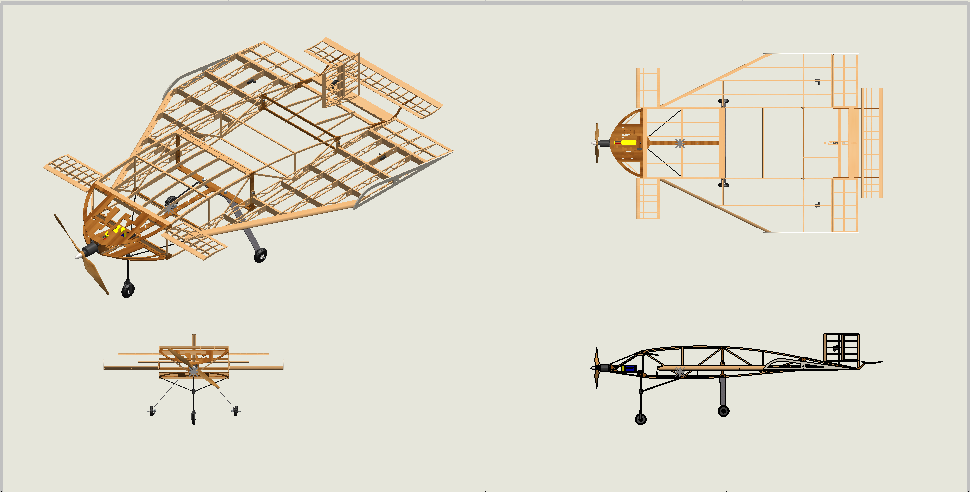

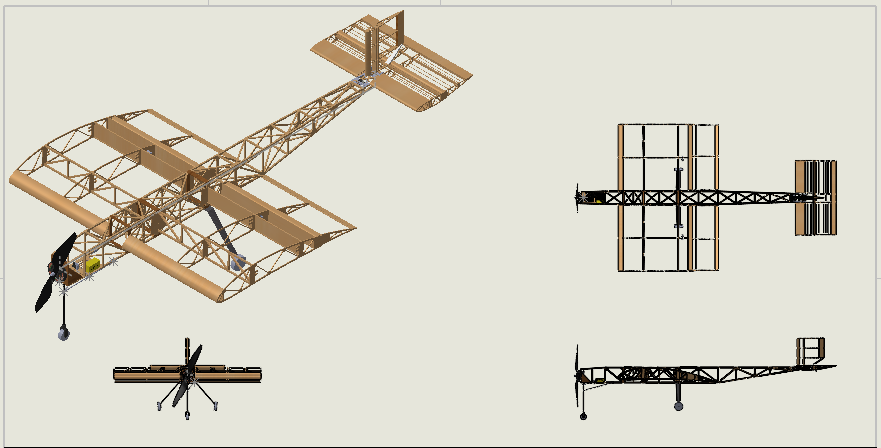

I am currently an advisor of Texas A&M's SAE Aero Design Micro Team, advising on the development of aerospace structures and material selection.

My senior design project focuses on robotics and simulation for a nuclear cleanup effort.

Additionally, I am an active member in the Meloy Engineering Innovation & Entrepreneurship Program, developing business, presentation, and leadership skills that complement my engineering background.

I am dedicated to learning new technologies and concepts, and I'm always ready for a new challenge.

Let's engineer dreams into reality!

Latest Projects

FreezeSense

Quadruped Mobility & Excavation

Corvette Restoration

Texas A&M Ideas Challenge Finalist

SAE Aero Design

Aggies Invent

Experience

After graduation, I will be joining Collins Aerospace in Lenexa, KS as a Mechanical Design Engineer. I will be a member of the OPSU department working on aircraft oxygen systems. This includes design and evaluation of aviation-grade safety systems throughout the lifecycle of the product.

Want to learn more?

Feel free to connect with me via email at [email protected] or explore my past projects in more detail.